Activated Charcoal, technically known as Activated Carbon, is one of the most exploited agents in the 21st century. The uses and benefits of activated charcoal are so numerous and diverse that it is axiomatic that one cannot live a day without directly using or being intimately impacted by multiple activated charcoal products or applications

Activated charcoal, activated carbon, activated coal, or activated biochar (the new “green” charcoal), are essentially just pure carbon.

Carbon

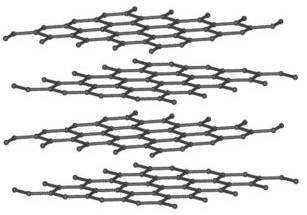

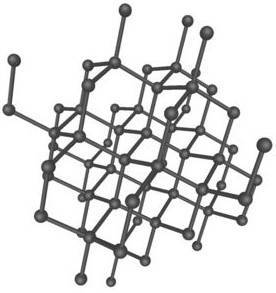

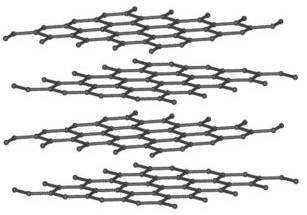

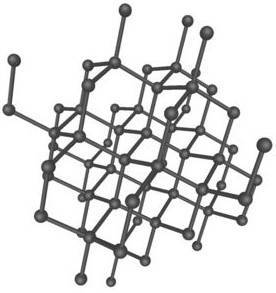

Carbon (pronounced /ˈkɑrbən/) is a chemical element with symbol C and atomic number 6. It is nonmetallic and tetravalent :C: (having four electrons available to form covalent chemical bonds). The word “carbon” comes from the Latin word for coal. Graphite, the most thermodynamically stable form of carbon (as in pencil “lead”) lies in layered sheets, which “shed” easily one from another. It is soft, black and a very good electrical conductor. Then there is diamond. It is highly transparent, has a very low

Carbon (pronounced /ˈkɑrbən/) is a chemical element with symbol C and atomic number 6. It is nonmetallic and tetravalent :C: (having four electrons available to form covalent chemical bonds). The word “carbon” comes from the Latin word for coal. Graphite, the most thermodynamically stable form of carbon (as in pencil “lead”) lies in layered sheets, which “shed” easily one from another. It is soft, black and a very good electrical conductor. Then there is diamond. It is highly transparent, has a very low

electrical conductivity, but the carbon atoms are so arranged that it is among the hardest materials known. To date carbon is known to form 10 million pure “organic” compounds, from solids (such as pure graphite or diamond) to gas or liquid compounds such as carbon dioxide (CO2) or carbon tetrachloride (CCl4).

electrical conductivity, but the carbon atoms are so arranged that it is among the hardest materials known. To date carbon is known to form 10 million pure “organic” compounds, from solids (such as pure graphite or diamond) to gas or liquid compounds such as carbon dioxide (CO2) or carbon tetrachloride (CCl4).

Carbon is what divides the world of chemistry into “organic” and “non-organic”. Any compound that contains as little as one carbon atom sets itself firmly within the camp of Organic Chemistry. But being an “organic” compound does not mean that something is “organic” in the more common sense of environmentally “safe”, or biologically more nutritious, or medicinally more healthy.

Then there is charcoal. Charcoal, activated charcoal, activated carbon, or activated biochar do distinguish themselves as being the “green” of the green, the quintessential of "SAFE". Except for specially sensitized activated carbons with otherwise toxic substances for specific industrial or pharmaceutical uses, plain charcoal remains an FDA Category I “Safe & Effective” product for the treatment of poisoning, and is GRAS (Generally Recognized As Safe).

Charcoal

“Char·coal” definition: a black or dark gray form of carbon, produced by heating wood or another organic substance in an enclosed space without air. (Encarta® World English Dictionary© 1999)

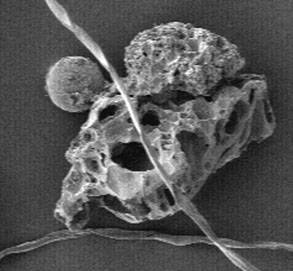

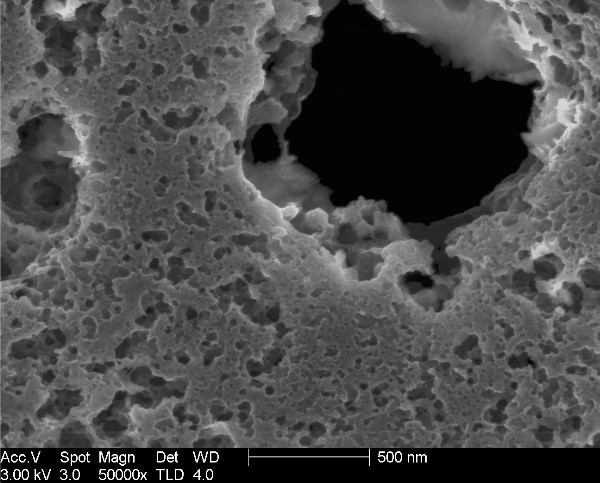

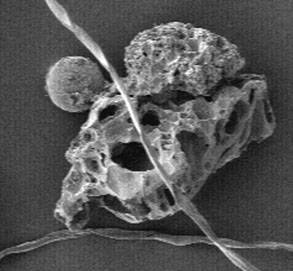

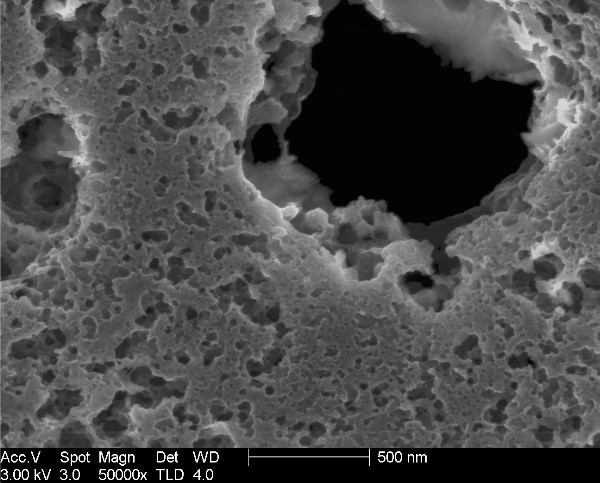

Having looked at carbon as a building block, let’s look at what makes charcoal so distinct  from the other forms of pure carbon. Irrespective of what the source is for charcoal, the carbon structure has been so altered from its original configuration as to present an extremely intricate and extremely porous internal matrix, giving it a large surface area available for adsorption ("adsorption" - the ability to bind atoms/molecules to a surface), or chemical reactions. What are some sources for charcoal?

from the other forms of pure carbon. Irrespective of what the source is for charcoal, the carbon structure has been so altered from its original configuration as to present an extremely intricate and extremely porous internal matrix, giving it a large surface area available for adsorption ("adsorption" - the ability to bind atoms/molecules to a surface), or chemical reactions. What are some sources for charcoal?

Historically charcoal has been made from wood, both softwoods and hardwoods. Charcoal’s first application (circa 1750 B.C.) was as a fuel for smelting ore. Charcoal burns hotter and cleaner than wood and so wood was converted to charcoal. How was charcoal originally made? Basically the same way it is made today around the world.

Making Charcoal

Great piles of wood are carefully arranged above or below ground so that once the fire is set the heat that is generated slowly "bakes" the wood, vaporizing off the moisture, vaporizing off volatile organic compounds (VOCs) leaving behind the hard black crusted charcoal.

Great piles of wood are carefully arranged above or below ground so that once the fire is set the heat that is generated slowly "bakes" the wood, vaporizing off the moisture, vaporizing off volatile organic compounds (VOCs) leaving behind the hard black crusted charcoal.

“We want ours to burn good and slow,” said Young Billy. “If he burns fast he leaves nowt but ash. The slower the fire the better the charcoal.”

Susan was watching carefully. “Why doesn’t it go out?” she asked.

“Got too good a hold,” said Young Billy. “Once he’s got a good hold you can cover a fire up and the better you cover him the hotter he is and the slower he burns. But if you let him have plenty of air there’s no holding him.”

Arthur Ransome

“Swallows & Amazons” 1930

How to make charcoal - Step by Step

Historically charcoal was used for much more than cooking and smelting ore. It was used to preserve lumber from rotting, bodies from decomposing when buried, preserving food and water on long sea voyages, making glass, controlling odors, and as a powerful medicinal.

But, charcoal is not “activated charcoal”, rather it is one raw material for the manufacture of activated carbons.

Activated Charcoal / Carbon

Production:

Activated charcoal/carbon is usually derived from charcoal or coal. There are two basic activation processes.

1. Charcoal is once again heated to very high temperatures (usually in the temperature range of 600-1200 °C) in the presence of oxidizing gases such a CO2, steam, or air.

2. Charcoal is impregnated with chemicals such as acids like phosphoric acid or bases like potassium hydroxide, or salts like zinc chloride, and then exposed to temperatures in the range of 450-900 °C. Both the heat activation and the chemical activation are believed to proceed simultaneously. Chemical activation is preferred over heat activation owing to the lower temperatures and shorter time needed for activating material. But there is the potential for contamination from trace residues such as zinc in the end product.

Both processes further erode the charcoal’s internal surfaces. This increases the adsorption capacity by creating an internal network of even smaller pores rendering it two to three times as effective as regular charcoal. But activated charcoal is not produced from wood alone. While coal is not charcoal, coal may be the largest source for the manufacture of activated charcoals. Other sources include wood, sawdust / sawchip, coconut shells, bamboo, peat, petroleum coke are the most common starting materials for making activated charcoal. Many other materials have been experimented with, but generally are not as economical, at least not until recently.

Technical Characteristic:

The surface area for activated carbons range from 500 m² to1500 m² or more per gram. If one could unfold all the microscopic surfaces in one teaspoon of activated carbon it could add up to the size of a football field.

Under an electron microscope (50,000 magnification), the high surface-area structures of activated carbon are more obvious. Individual particles are intensely convoluted with micro porosity in the range of a few nanometers. These microscopic pores are divinely engineered to offer binding sites for thousands of different chemicals.

Under an electron microscope (50,000 magnification), the high surface-area structures of activated carbon are more obvious. Individual particles are intensely convoluted with micro porosity in the range of a few nanometers. These microscopic pores are divinely engineered to offer binding sites for thousands of different chemicals.

Physically, activated carbon binds materials by electrostatic Van der Waals (intermolecular) forces.

There are however chemicals that do not bind well to activated carbon including alcohols, glycols, ammonia, strong acids and bases, metals and most inorganics such as lithium, sodium, iron, lead, arsenic, fluorine, and boric acid. Activated carbon does adsorb iodine very well and in fact the iodine number (mg/g) is used as an indication of total surface area.

Since activated carbon does not adsorb inorganic compounds well activated carbons are sometimes “sensitized” with various chemicals to improve the adsorptive capacity for some inorganic compounds such as hydrogen sulfide, ammonia, formaldehyde, radioisotopes, and mercury. This function is called chemisorption.

Classifications:

Activated Carbons (AC) are most commonly divided into three categories based on their physical characteristics.

Powdered Activated Carbon (PAC)

Traditionally, activated carbons are made into powders or fine granules with an average diameter between .15 and .25 mm. PAC is made up of crushed or ground carbon particles, 95–100% of which will pass through a 50 to 80 mesh sieve.

Granular Activated Carbon (GAC)

Granular activated carbon is relatively larger in particle size compared to powdered activated carbon. Because GAC has a smaller external surface area than PAC it is often wrongly assumed that GAC has less total surface area. It must be remembered that the surface area of activated carbon is by far internal and not external. GAC is preferred for all adsorption of gases and vapors as their rates of diffusion are faster. Granulated activated carbons are also used for water treatment, deodorizing and the separation of components in a flow system. GAC can be either in the granular form or extruded as pellets. GAC is designated by sizes such as 6x10, 8x16, 12x30, or 20x50 for water/liquid applications and 4x6, 4x8 or 4x10 for air/vapor applications. A 20x40 GAC is made of particles that will pass through a U.S. Standard Mesh Size # 20 sieve (0.84 mm) (generally 85% will pass through) but be retained on a U.S. Standard Mesh Size # 40 sieve (0.42 mm) (generally 95% will not pass through). The American Water Works Association (AWWA - 1992) uses the Mesh Size # 50 sieve (0.297 mm) as the minimum GAC size. Applications look for the best balance of size, surface area, and headloss characteristics.

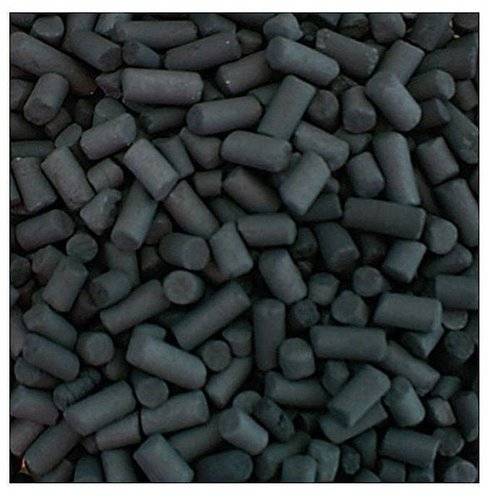

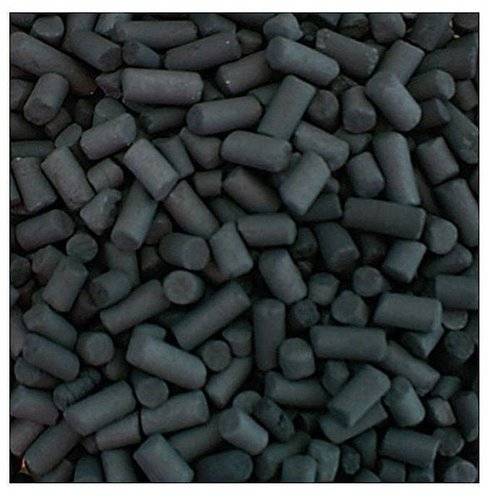

Extruded Activated Carbon (EAC)

Extruded Activated Carbon (EAC)

Extruded or Pellet AC consist of extruded and cylindrical shaped activated carbon with diameters from 0.8 to 45 mm. These are typically used for air/gas applications because there is a low pressure drop as the air/gas moves through, and it has a high mechanical strength and low dust content.

Impregnated Activated Carbon (IAC)

These are porous activated carbons that are impregnated with inorganic elements such as iodine, silver, or cations such as Al, Mn, Zn, Fe, Li, and Ca. These are used to treat flu gases as in coal-fired generation plants or in air pollution control especially in museums and galleries. Due to its antimicrobial/antiseptic properties, silver impregnanted activated carbon is used as an adsorbent in earth-bound water purifications systems and in the orbiting space station. IAC is also used for the adsorption of mercaptans and H2S (often found in wines). 50%+ by weight adsorption of H2S has been reported.

Polymers Coated Activated Carbon (PCAC)

Activated carbons can be coated with a biologically compatible polymer to give a smooth and permeable coat that does not block the pores. The resulting PCAC is useful for hemoperfusion. In AC hemoperfusion large volumes of blood are passed over/through a bed of GAC or PCAC in order to remove toxic substances from the blood.

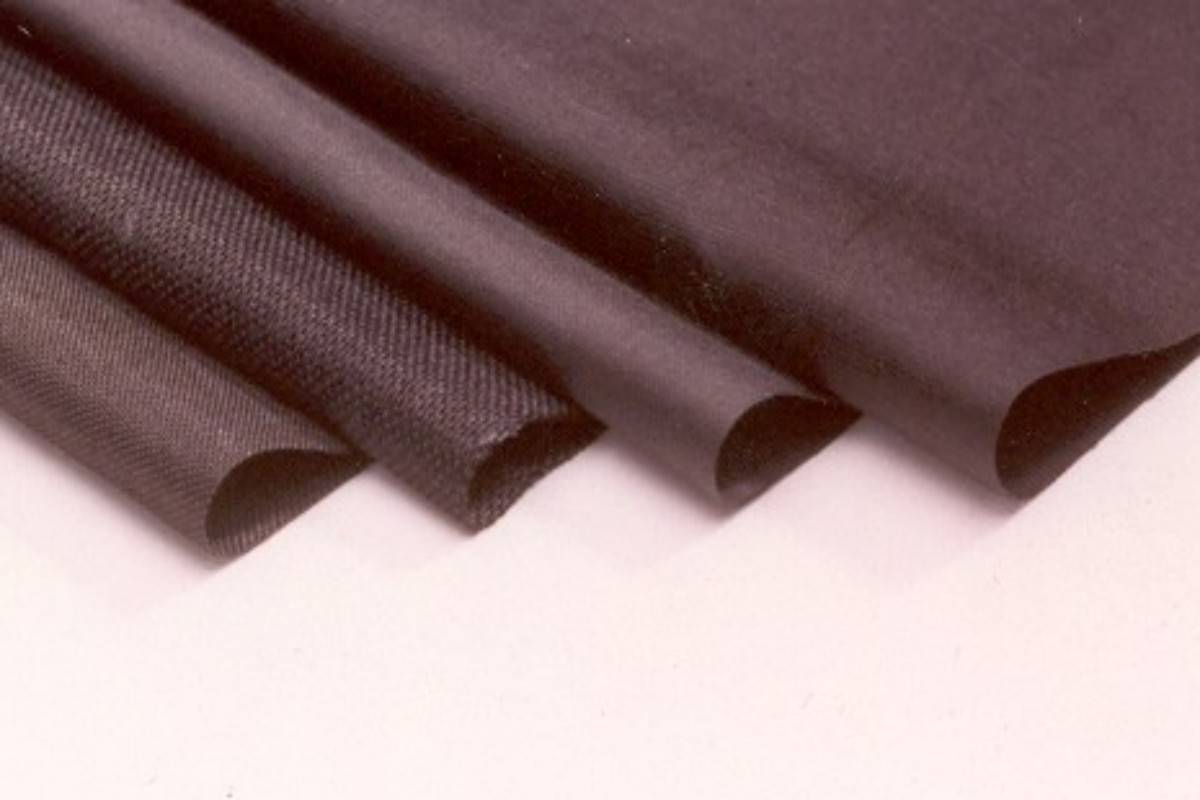

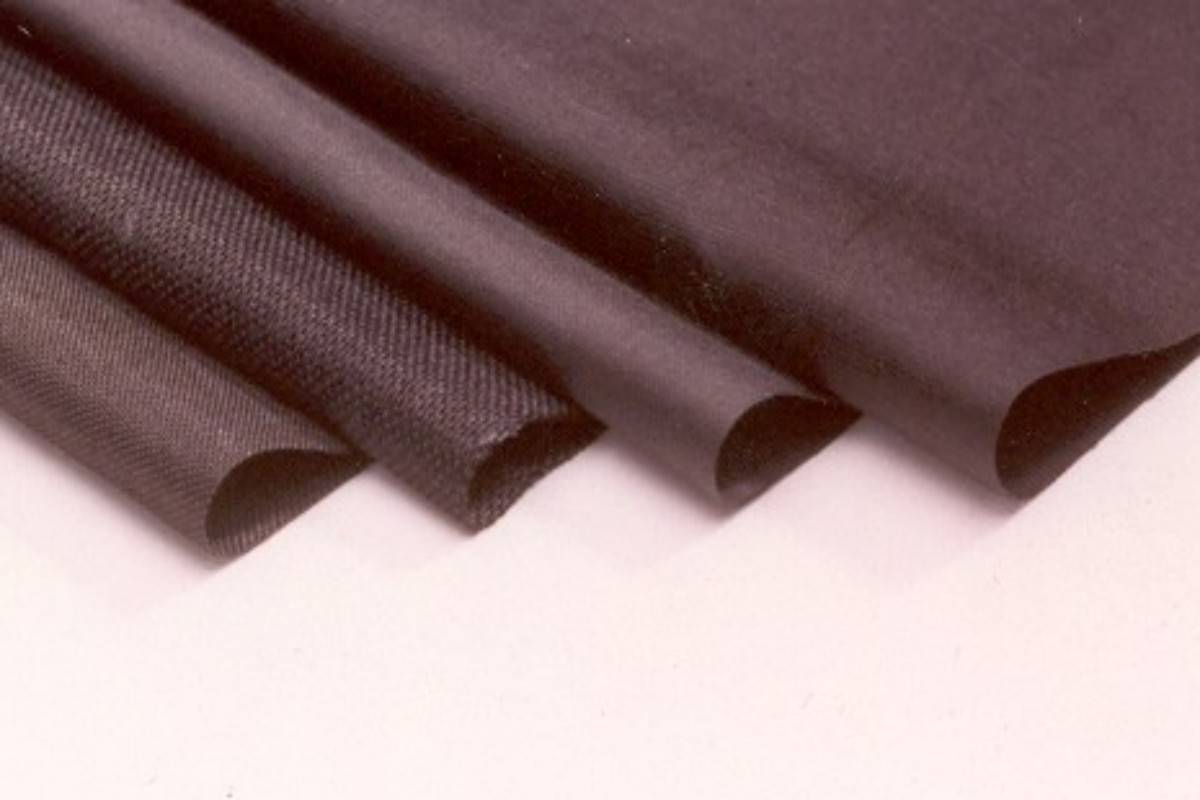

Activated Carbon Cloth (ACC)

Activated Carbon Cloth (ACC)

Activated carbon is also available as cloths and fibers. ACC is used by the military for Nuclear Biological Chemical (NBC) protective clothing, socks and gloves. It is also used in wound dressings, protective masks, for the protection of artifacts from tarnish and degradation, oil mist filters for compressors, gas sensors, electrodes, water purification, and more.

Biochar Activated Charcoal (BAC)

Biochar is the most recent addition to the activated carbon family. Biochar carbons are those produced by a pyrolysis process with extremely low carbon emissions, a carbonization process that takes raw products straight through to the activation stage in less than an hour depending on the temperature range. The pyrolysis process can be designed to maximize for energy to run electrical turbines, or to produce biofuels. Both these processes result in a low activity biochar with a high ash content. Or the process can be designed to produce highly active biochars with a low ash content, without wasting valuable carbon to the atmosphere. Biochars are seen as more environmentally responsible compared to charcoals produced by conventional burning practices which emit large amounts of carbon. Carbon retention is on the order of 96% from pyrolysis, compared to 50% from conventional methods.

Today the emphasis, rightly so, is on "GREEN", and even though charcoal/biochar is black, you just can't get any greener than charcoal. "Carbon Positive" means adding carbon saturated compounds to the atmosphere - as in fossil-fueled motors. "Carbon Neutral" means maintaining a zero carbon emissions footprint - adding no more carbon to the atmosphere than is sequestered back into the soil, or offsetting carbon emissions with carbon reduction - solar panel or wind generator manufacturing. Then there is "Carbon Negative", capturing and holding more carbon in the soil than is emitted to the atmosphere. Charcoal, and especially pyrolized biochars, is distinctly "Carbon Negative", making them, hands down, the "Green" of the green.

Diversity:

As diverse as carbon is in the chemical world, just so is the diversity of activated charcoal in its applications. One activated charcoal manufacturing company logo goes “A thousand applications today, a thousand and one tomorrow”. It might also be said of charcoal “Imagine the Possibilities”.

In review, we drink water filtered by it; breath air scrubbed with it; eat food purified through it, wear clothes made with it; grow our food and flowers in it; go to war with it; preserve things in it; enjoy hundreds of dishes cooked by it; we move mountains with it; we make the night sky sparkle with it; we take it with us to the bottom of the deepest oceans and out into space; swim in water washed with it; paint or draw our inspirations with it; and we record man’s history of successes and mistakes dipped in it. Not least and not last, charcoal is called upon to clean up many of our technological mistakes. No wonder we naturally warm up to it.

Properties:

Not all activated carbon are created equal. In fact there are well over 150 different specialized activated carbons for multiple more applications. But the desired end result is most often the ability to remove something that is deemed undesirable. It may be CO2 from the air in nuclear submarines, SO2 from fuel cells in the new hybrid cars, unwanted color from vegetable oil, unpleasant odor from pharmaceuticals, biological chemicals in combat suits, drug poisoning in cases of attempted suicide, liver toxins in liver dialysis machines... To do this manufacturers tailor make activated carbons to target specific sized molecules with specific chemical characteristics. To help differentiate these activated carbons the industry has recognized certain measurable properties.

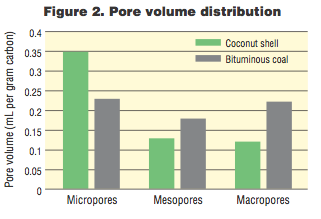

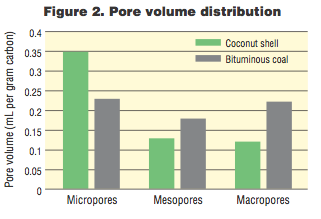

Porosity

As mentioned earlier, the porosity of activated carbons figure highly in their adsorption capabilities. Science has broadly recognized three categories: macroporous ("large" - greater than 50 Å, or larger than 5 nm); mesoporous ("medium" 20 Å - 50 Å, or 2 - 5 nm); and microporous ("small" - less than 20 Å, or up to 2 nm). Here is a simple graph thart shows the difference in pore size distribution between coconut-base and Bituminous-based activated carbons.

Iodine Number

Many carbons prefer to adsorb small molecules. The Iodine number is a basic measurement used to characterize activated carbon performance. It is a measure of activity level (higher numbers indicate a higher degree of activation), often measured in mg/g (common range 500-1200 mg/g). The Iodine number represents the micropore content of the activated carbon relative to the amount of iodine adsorbed from solution. Iodine Number coincides with Surface Area measurements of activated carbon between 900 m²/g and 1100 m²/g. Iodine Number is the standard measure for water/liquid applications. The Iodine number is essentially a measure of the iodine adsorbed into the pores of an activated carbon of interest, indicating the pore volume that is available. For example, GAC used for water treatment have Iodine numbers ranging from 600 to 1100mg/g.

Molasses

Some activated carbons are more inclined at adsorb large molecules. A molasses number indicates the macropore content of the activated carbon (larger than 20 Å or 2 nm) by adsorption of molasses from solution. A high molasses number indicates a high adsorption of big molecules (range 95-600). Since color molecules typically are large, the Molasses Number is a measure of the degree of decolorization. Due to the size of color bodies, the molasses number represents the potential pore volume available for larger adsorbing activated carbons.

Tannin

Tannins have a mixture of large and medium size molecules. Activated carbons that combine macropores and mesopores adsorb tannins very well. This ability to adsorb tannins is reported in parts per million concentration (range 200 ppm-362 ppm).

Methylene blue

Activated carbons with a mesopore (20 Å - 50 Å, or 2 - 5 nm) structure adsorb medium size molecules like the dye Methylene Blue. Methylene Blue adsorption is reported in g/100g (range 11-28 g/100g).

Dechlorination

Some activated carbons are evaluated on their ability to remove chlorine. The dechlorination half-value distance equals the depth of AC required to reduce the chlorine level of a liquid stream from 5 ppm to 3.5 ppm. The lower the half-value the better the performance.

Apparent density

The higher the density the greater volume activity. Typically this indicates a better quality activated carbon.

Hardness/abrasion number

It is a measure of the activated carbon’s resistance to wearing away due to friction as in water filters that use backwashing. The hardness of activated carbons vary greatly, depending on the raw material and activation level.

Ash content

Ash content reduces an activated carbon's activity potential. Ash content reduces the ability to reactivate used carbons. If metal oxides (Fe2O3) are present in the activated carbon, they can leach out and cause discoloration. Acid or water soluble ash content is more problematic than total ash content. Soluble ash content can be very important for fish aquarium enthusiasts. A low soluble ash content is vital for marine, freshwater fish and reef tanks to minimize the risk of heavy metal poisoning and excessive plant/algal growth.

Carbon tetrachloride activity (CTC)

The Carbon Tetrachloride number (45 - 70% by weight) measures the porosity of an activated carbon for air/vapor applications according to the amount of carbon tetrachloride vapor it will adsorb.

Particle size distribution

The smaller the particle size of an activated carbon, the more access there is to the surface arearesulting in faster rate of adsorption. That is a major benefit in water/liquid applications, but in air/vapor phase systems, where air flow may be significantly slowed due to the density of the AC, a larger particle size is often more practical and economical. Because flow pressure is directly influenced by the size of particles and how tightly they are packed, careful attention to particle size distribution will impact the economic value and efficiency of a filtering system.

Applications:

- Air filters in gas masks, filter masks, air compressors.

- Food coloring

- Gas purification

- Gold purification

- Medicine: liver and kidney dialysis machines, laser surgery, breast cancer surgery, stomach decontamination from drug/food poisoning...

- Metal extraction

- Metal finishing - the purification of electroplating solutions, as in bright nickel-plating solutions.

- NBC suits

- Fabrics: activated carbon cloth, artificial silk...

- Nuclear power plants

- Recycling solvents

- Commercial Printing Inks

- Rye grass seed industry

- Sewage treatment

- Snow avalanche control - helping to melt snow

- Soil enhancement

- Sound systems - "cleaning" out bad background noise

- Toxic soil cleanup from chemical spills or accumulation of chemical spraying

- Volatile organic compounds capture from painting, dry cleaning, gasoline dispensing operations, and other processes.

- Water purification: aquariums, swimming pools, domestic & municipal water systems, recycling precious water on the orbiting space station (cost $10,000/liter)

One activated carbon manufacturer motto goes "A thousand applications today, a thousand and one tomorrow". Another asks, "Imagine the Possibilities!"

In Summary:

We drink water filtered by it; breath air scrubbed with it; eat food purified through it; wear clothes made with it; grow our food and flowers in it; go to war with it and heal sick bodies with it; preserve things in it; enjoy hundreds of dishes cooked by it; we move mountains with it; we make the night sky sparkle with it; we take it with us to the bottom of the deepest oceans and out into space; swim in water washed with it; paint or draw our inspirations with it; and we record man’s history of successes and mistakes dipped in it. Not least and not last, activated charcoal is called upon to clean up many of our technological mistakes. No wonder we naturally warm up to it.

Carbon (pronounced /ˈkɑrbən/) is a chemical element with symbol C and atomic number 6. It is nonmetallic and tetravalent :C: (having four electrons available to form covalent chemical bonds). The word “carbon” comes from the Latin word for coal. Graphite, the most thermodynamically stable form of carbon (as in pencil “lead”) lies in layered sheets, which “shed” easily one from another. It is soft, black and a very good electrical conductor. Then there is diamond. It is highly transparent, has a very low

Carbon (pronounced /ˈkɑrbən/) is a chemical element with symbol C and atomic number 6. It is nonmetallic and tetravalent :C: (having four electrons available to form covalent chemical bonds). The word “carbon” comes from the Latin word for coal. Graphite, the most thermodynamically stable form of carbon (as in pencil “lead”) lies in layered sheets, which “shed” easily one from another. It is soft, black and a very good electrical conductor. Then there is diamond. It is highly transparent, has a very low

electrical conductivity, but the carbon atoms are so arranged that it is among the hardest materials known. To date carbon is known to form 10 million pure “organic” compounds, from solids (such as pure graphite or diamond) to gas or liquid compounds such as carbon dioxide (CO2) or carbon tetrachloride (CCl4).

electrical conductivity, but the carbon atoms are so arranged that it is among the hardest materials known. To date carbon is known to form 10 million pure “organic” compounds, from solids (such as pure graphite or diamond) to gas or liquid compounds such as carbon dioxide (CO2) or carbon tetrachloride (CCl4).

from the other forms of pure carbon. Irrespective of what the source is for charcoal, the carbon structure has been so altered from its original configuration as to present an extremely intricate and extremely porous internal matrix, giving it a large surface area available for adsorption ("a

from the other forms of pure carbon. Irrespective of what the source is for charcoal, the carbon structure has been so altered from its original configuration as to present an extremely intricate and extremely porous internal matrix, giving it a large surface area available for adsorption ("a

Under an electron microscope (50,000 magnification), the high surface-area structures of activated carbon are more obvious. Individual particles are intensely convoluted with micro porosity in the range of a few nanometers. These microscopic pores are divinely engineered to offer binding sites for thousands of different chemicals.

Under an electron microscope (50,000 magnification), the high surface-area structures of activated carbon are more obvious. Individual particles are intensely convoluted with micro porosity in the range of a few nanometers. These microscopic pores are divinely engineered to offer binding sites for thousands of different chemicals.